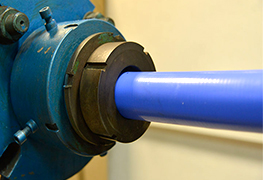

Hose Strength Testing

Our team of skilled development engineers and experienced technologists are focused on the continuous development of advanced capability products.

Our team of skilled development engineers and experienced technologists are focused on the continuous development of advanced capability products.

Maintaining a market leading position is assured with our in-depth knowledge of industry requirements and product innovation.

Maintaining a market leading position is assured with our in-depth knowledge of industry requirements and product innovation.

Structured prgramme of material testing in accordance with both international and customer specific standards.

Structured prgramme of material testing in accordance with both international and customer specific standards.

In house accelerated ageing and dynamic testing of finished products to replicate long term functionality.

In house accelerated ageing and dynamic testing of finished products to replicate long term functionality.

Regular on-site visits ensure our engineers are up-to date with customer needs.

Regular on-site visits ensure our engineers are up-to date with customer needs.

Unique process,production and test machinery is designed and built in-house to optimise capabilities of both product development and volume production.

Unique process,production and test machinery is designed and built in-house to optimise capabilities of both product development and volume production.

Accredited to Ts16949:2009 and ISO9001:2008,quality standards are maintained to the highest possible international levels.

Accredited to Ts16949:2009 and ISO9001:2008,quality standards are maintained to the highest possible international levels.

The Factory is also committed to working towards environmental standard ISO 14001.

The Factory is also committed to working towards environmental standard ISO 14001.

Considerations Before Cutting Silicone Hoses:

2.1. Hose Type and Reinforcement: Identify the type of silicone hose you are working with and determine its reinforcement method. Some hoses have multiple layers, while others may have a single reinforcement layer.

2.2. Hose Diameter: Measure the diameter of the hose accurately. This will help you determine the correct cutting tool and ensure a clean and precise cut.

2.3. Purpose of the Hose: Consider the purpose of the hose and the specific requirements of your application. Ensure that cutting the hose will not compromise its functionality or structural integrity.

Tools Required for Cutting Silicone Hoses

3.1. Sharp Utility Knife: A sharp knife with a fresh blade is essential for achieving clean and precise cuts. Dull blades can tear the hose, leading to uneven edges.

3.2. Measuring Tape: Use a measuring tape to mark the desired length accurately.

3.3. Masking Tape: Applying masking tape around the hose before cutting can help prevent fraying and provide a cutting guide.

Step-by-Step Guide to Cutting Silicone Hoses

4.1. Prepare the Hose: Clean the hose surface to remove any debris or dirt that could interfere with the cutting process.

4.2. Mark the Cutting Point: Use a measuring tape to mark the desired length of the hose. Apply a piece of masking tape around the hose at the marked point. This will serve as a guide for the knife.

4.3. Secure the Hose: Firmly hold the hose in place using clamps or a vise to prevent it from moving during the cutting process.

4.4. Make the Cut: With a steady hand, carefully align the utility knife with the masking tape guide and apply downward pressure. Use a continuous, smooth motion to cut through the silicone hose. Take your time to ensure a clean and straight cut.

4.5. Inspect the Cut: After cutting, inspect the edges of the hose for any signs of fraying or unevenness. If needed, trim any loose strands using a pair of sharp scissors.

Post-Cutting Considerations

5.1. Smooth the Edges: Smooth the edges of the cut with sandpaper or a deburring tool to remove any roughness and prevent potential leaks.

5.2. Reattach Fittings: If the hose had fittings attached, reattach them using appropriate methods such as hose clamps or adhesive designed for silicone materials.

Conclusion

In conclusion, cutting a silicone hose is possible, provided you take the necessary precautions and follow the correct steps. By using the right tools and techniques, you can modify silicone hoses to meet your specific needs. Remember to consider the type of hose.